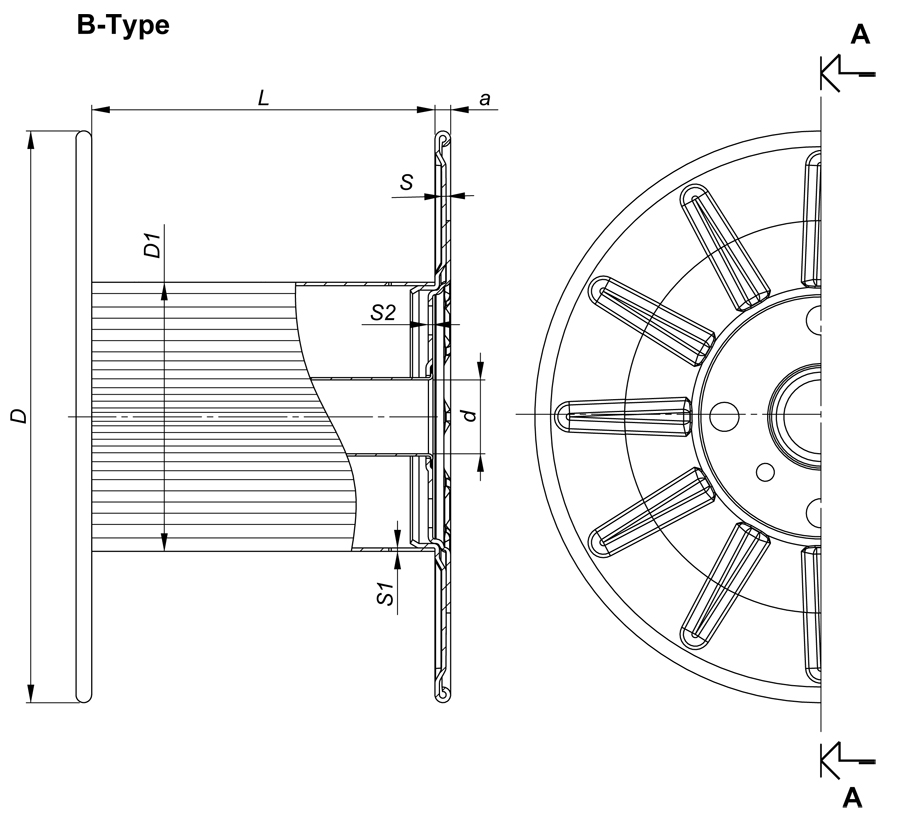

Spool B-Type

Spools B40, B60, B80/17 and B80/33 for the winding and one-way/multiple shipping of rope for tires, commonly called tire-cord, but also used for the winding of hose wire, saw wire and special wires.

/

Spool B-Type

Spools B40, B60, B80/17 and B80/33 for the winding and one-way/multiple shipping of rope for tires, commonly called tire-cord, but also used for the winding of hose wire, saw wire and special wires.The range of available B-type consists of the following categories:

- Spools of the N series, usually characterized by a lightweight structure and by the presence of a driving plate with a standard diameter (153mm). They are particularly suitable for the winding of tire-cord and are powder coated (one or two-colors).

- Spools of the S series, characterized by a reinforced structure having increased thicknesses of metal sheets, and by the presence of a driving plate with increased diameter (175mm) and welded to the flange by means of a double electro-welding (class A). They are suitable for the winding of thin wires and hose wires and are powder coated (one or two-colors). For the winding of saw wire, the wire involved in the production of solar cells, electrolytic galvanization according to UNI EN ISO 2081:2008, available with silver or gold passivation, is provided. The thickness of the materials used for the production of B-type spools varies depending on the specific application and on the customer specification, up to a maximum of 2mm thickness for each component.

The tightness of the welds and the spool strength are constantly monitored by breaking tests and testing of deformation under pressure, which are performed on all B-type spools manufactured by A.Appiani srl.

/

STANDARD

Electro-welding with Nr 8 class A points for one-way shipping spools (usually saw wire)

back/

OPTIONS

Electrolytic galvanization as per UNI EN ISO 2081:2008 – golden or silver passivation – for winding of saw-wire

backApplication of either Nr 1 or Nr 2 reinforcing plates into the barrel (spot-welded)

backSpecial holes on driving plates (slotted holes or other) according to specific requests

backDriving plate having increate diameter (type S) and double spot-welding of class A to the flange

backTightening clip on the flange, stamped on the flange or made of galvanized wire

backDriving plate having extra-increased diameter for particular heavy duty applications

back/

GALLERY